The issue of contamination in Sindh’s cotton has become a major concern for the spinning sector. Many spinning mills across Pakistan are facing serious problems as cotton from Sindh is increasingly being delivered with foreign materials such as polypropylene, human hair, and candy or chip wrappers, causing major disruptions in spinning operations. Despite the use of advanced machinery mills are struggling to maintain quality.

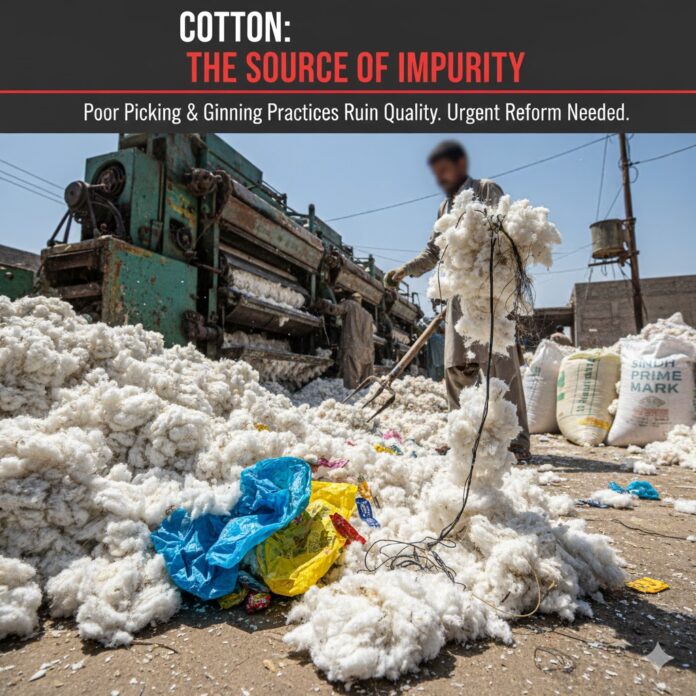

In Sindh, nearly all phutti is supplied in polypropylene bags, and poor picking and storage practices have resulted in higher contamination levels. Although Sindh cotton is traditionally known for its better quality, these contamination issues have severely undermined its reputation. Most ginners in Sindh do not take contamination control seriously, and even certified cotton such as Prime Mark and BCI is not free from impurities. Punjab’s cotton, while slightly better in quality, also faces contamination challenges, though a few ginners there have introduced systems to minimize it. However, none are able to label their bales as contamination-free

Sindh remains the leading cotton producer so far, with total arrivals reaching 2,528,176 bales, compared to Punjab’s 1,909,080 bales. Yet, the contamination issue is not only affecting spinning mills but also harming Pakistan’s textile exports. The spinning industry is already burdened with high taxation, liquidity shortages, slow yarn sales, delayed payments, and rising energy costs. The growing contamination problem is further threatening the survival of an industry that holds immense potential for foreign exchange earnings. This issue needs to be urgently addressed by ginners, as the sustainability of the textile sector will ultimately the survival of the ginning industry.